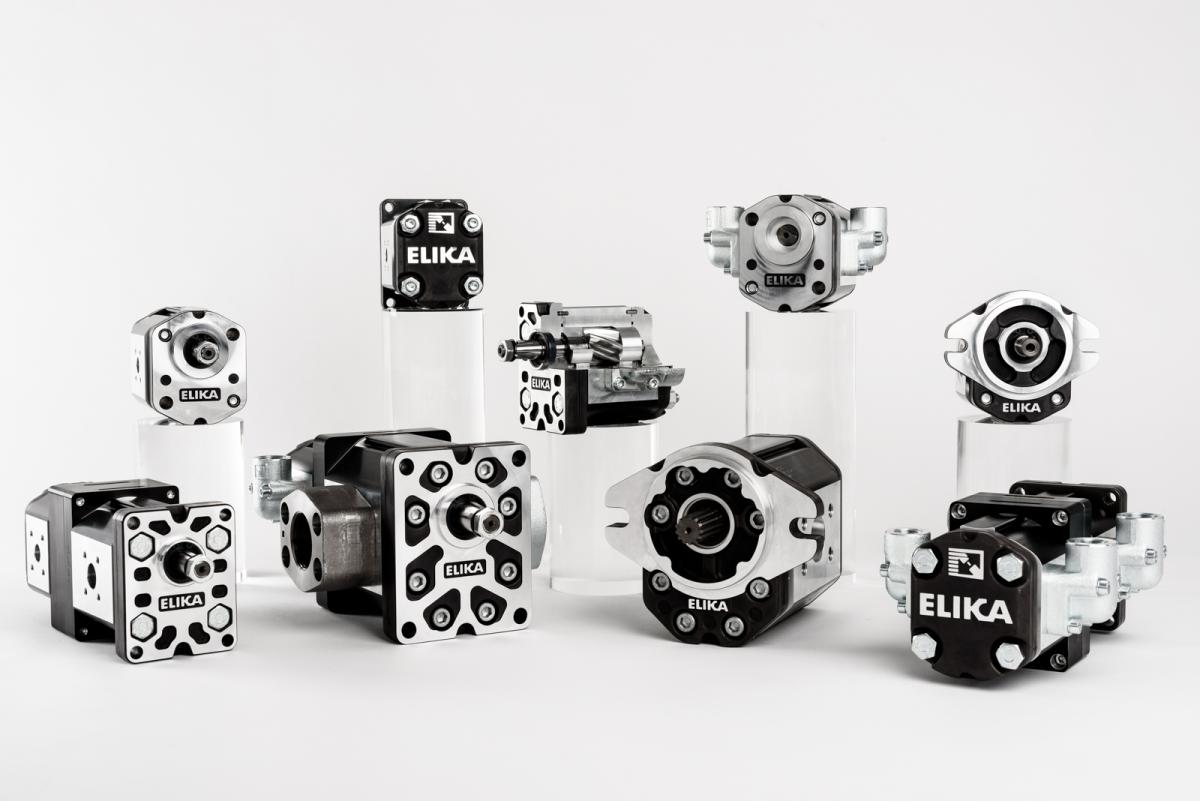

ELIKA is the low-noise, high-efficiency, low-pulsation gear pump developed in close collaboration with the Faculty of Engineering at the University of Bologna through the generation of a dedicated design software.

Overview:

ELIKA is a solution for all applications requiring low levels of noise and high-levels of efficiency, particularly at low speeds. ELIKA in fact reduces noise emissions by as much as 15 dBA with respect to traditional external gear pumps. Maximum working pressures are similar to those for the GHP series (cast iron/aluminium), thus reaching 300 bar. The particular tooth profile without encapsulation furthermore allows a considerable reduction in pressure oscillations and vibrations transmitted to other components connected to the pump (hoses, tank and valves), producing numerous advantages in the circuit. The helical gear effectively guarantees continuity of movement despite the low number of teeth. The low number of teeth also significantly reduces the fundamental frequencies of noise output, making the sound particularly pleasant.

Elika's Gear shape

Performance:

The particularly low level of noise produced by the ELIKA pump makes it particularly suitable for applications which currently employ much more expensive technologies such as screw pumps, vane pumps, or internal gear pumps. ELIKA, with its characteristics, is the ideal solution regarding a wide range of specifications such as rotation speed, operating pressure and viscosity. The structure of the ELIKA pump minimises leaks and maximises volumetric efficiency in all conditions. ELIKA is therefore particularly suited for applications, which use inverters or variable-speed drives to regulate the speed of the actuators.

Technical Mention Prize at EIMA 2018

"Double Elika is a Solution for external gear pumps that allows the same design of gears previously reserved for individual pumps to be used in modular architectures, to reduce vibrations and noise."